Provide your workers with unmatched security. Our Roof Anchor Points are an effective fall prevention support system in high-risk environments allowing you to move freely with peace of mind.

Roof anchor points

Specialists in roof anchor point design, installation, inspections & certifications

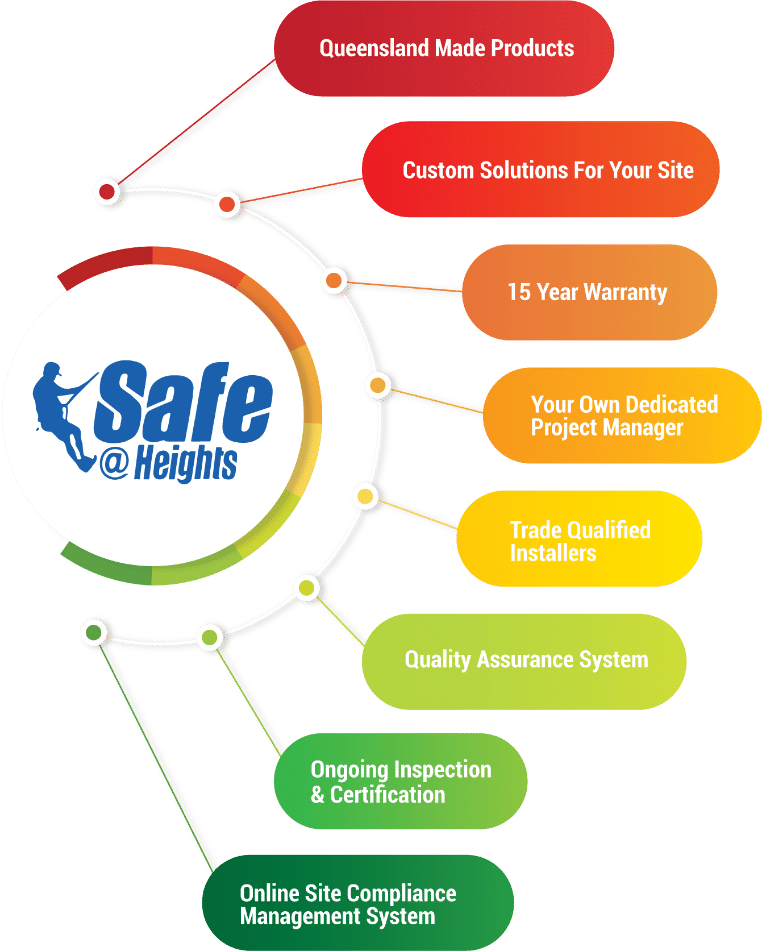

Our experienced and friendly team are here ready to help you. Whether you need an inspection or audit of existing roof anchors, a quote for a new design and installation or just have a question. There is nothing we can’t assist you with. As the manufacturer and installer of Queensland Made Anchor Points we have the experience and knowledge of legislation you can trust and rely on.

Please choose from the below options or keep reading down the page for additional information on roof anchors.

Learn More About Roof Anchor Points

Fall arrest roof anchor points system is considered the last line of defense against a fall. When working at heights and using anchor points, it is vital that the user understand the type of roof anchor they are attached to and what it is capable of. Never attach to a system which you are unfamiliar with. As a general rule, always work in fall restraint. This means ensuring that you are not able to fall in the first place.

Most roof anchors have a rating of 15kN and can be used for either fall arrest, abseil or both. It is important to understand this as using the wrong type can cause damage to the anchor or structure.

There are only two types,

- Fall arrest

- Abseil

Fall arrest points can be used for fall arrest and fall restraint. They must be rated to a minimum of 15kN and comply with AS1891.4 and AS5532.

Abseil points can be used for abseil, fall arrest and fall restraint and must have a minimum rating of 15kN and comply with AS1891.4, AS5532 and AS4488. Under AS1891.4 it does allow for abseil anchor points to have a lessor rating of 12kN, however if this is the case then they are not able to be used for fall arrest or fall restraint. Therefore we do not recommend installing an abseil system with only a 12kN rating.

There are many different configurations of anchor points, each designed for different types of installations. The main types are

- Surface mounted (directly to metal roof via rivets and screws)

- Purlin mounted (directly into the purlin)

- Concrete glue in

- Friction

- Steel fix

Which one you choose will depend upon your roof type, work to be carried out, design of the system and ongoing maintenance considerations. In general, we recommend surface mounted roof anchor points for the standard metal roof as it is easier to inspect which also makes the ongoing inspections cheaper

All anchor points must be inspected and certified by a competent and licenced person every 12 months. If they are being used on a regular basis or are in a harsh environment then it should be more often. But as a general rule 12 months is fine. This 12 monthly inspection requirement comes from AS1891.4

Most roof anchors only require a visual inspection. However glue in and friction type (usually installed in concrete) must be load tested to 50% of their nominated capacity for 3 minutes. For a 15kN rated anchor points that is 7.5kN. The only exemption to this is for concrete mounted if they have been cast in.

It is vital that workers understand the difference between working in fall arrest and fall restraint when using an anchor point safety system. Many workers get this wrong and unfortunately this can result in serious injury or death. From our many years of experience we have developed four methods of attachment that can be used when working at heights and using any fall arrest system.

Click here to read more about our Four Methods of Attachment

The methods we have developed form the basis for our video induction and training system we have developed. This system can be used via our new App or our training portal. This system was developed to ensure that if a worker is accessing your roof you can feel confident that they understand how to do so safely. As the owner of a fall arrest system you have a legal duty under the Work Health and Safety Act to provide this information and training. For more information about our system and how we can tailor it to your specific needs please contact us.

All permanently installed roof anchors must only be installed and certified by an authorised installer. In Queensland the installer must also hold the appropriate QBCC licence. Any Height anchors not installed by an authorised and licenced installer must be deemed uncertified and should never be used. For example, we see roof anchors which have been installed by plumbers or roofers who do not hold the appropriate QBCC Licence to install or certify height safety anchors. They also are not authorised by the manufacturer of that particular product so therefore are not permitted to install.

Never use an unlicensed or unauthorised installer for the installation of roof anchors. As a PCBU you will be liable for any injury if you have used such a company.

Safe@Heights holds a QBCC licence for both Structural Steel Fabrication and Erection and Builders (low rise), which authorises us to design, install, inspect and certify fall arrest anchor points. We also are authorised and trained installers for Sayfa, 3M (formally Capital Safety), Ferno and Safety Link. All our installers are full time employees. They are all experienced trade qualified carpenters who take pride in their workmanship. We don’t subcontract any of our installations. We guarantee quality, reliability and professional service.

When using a roof anchor points system it is a legal requirement to establish emergency and rescue procedures. The rescue plan must have been tested to ensure that it is effective. It is the responsibility of the supervisor to ensure that when using an anchor points system as a control measure,

- There is an effective rescue plan in place

- The rescue equipment is fit for purpose

- The rescue equipment is at the actual site of the works

- That a trained rescue person is on standby during the works and

- A rescue can be executed in under five minutes

Anyone using roof anchors must take into consideration that if they were to fall they will sustain injuries. Even a relatively short fall will exert enormous force through the person’s body. Once the fall has been arrested and the person is suspended in their harness, it is vital that the rescue plan is immediately put into action and the person is safely rescued in under 5 minutes. Every second someone is suspended the risk of them suffering from suspension intolerance increases. Once suspended in an upright position the harness leg straps cause pressure on the leg veins which in turn reduces the amount of blood being returned to the heart and this causes the heart to slow. This may lead to renal failure and eventually death, depending upon the person’s susceptibility to the condition. Other factors such as the injuries they have sustained during the fall, heat and dehydration can increase the risks. After 5 minutes of being suspended the risk of suspension intolerance increases dramatically.

Prior to commencing work using a roof anchor points system, you must ensure the following

- All higher levels of control have been considered first prior to using an anchor point system

- Workers are wearing a full body fall arrest harness that is fit for purpose, has been certified and correctly fitted

- All attachment equipment has been certified and is fit for purpose

- The harness has been fitted with suspension support straps

- Workers wear adequate head protection to protect their head in the event of a fall

- A fit for purpose rescue plan has been put in place

- A certified fit for purpose rescue kit has been set up and ready for immediate deployment

- The supervisor has nominated a rescue person who has been trained in rescue and is competent for the role

If you put all of the above steps in place prior to commencing work and attaching to the roof anchor points you will be in a much better position in the event of having to perform a rescue. Of course the best course of action is to ensure you use a connection method that will prevent you from falling in the first place. We recommend working in fall restraint at all times.

For more information on any of our systems please contact us

Companies we have proudly worked with

Request a Quote

Get in touch